LOW RISK

LOW RISK

CONCEPT

CONCEPT

DESIGN

DESIGN

CAPABLE

CAPABLE

available

available

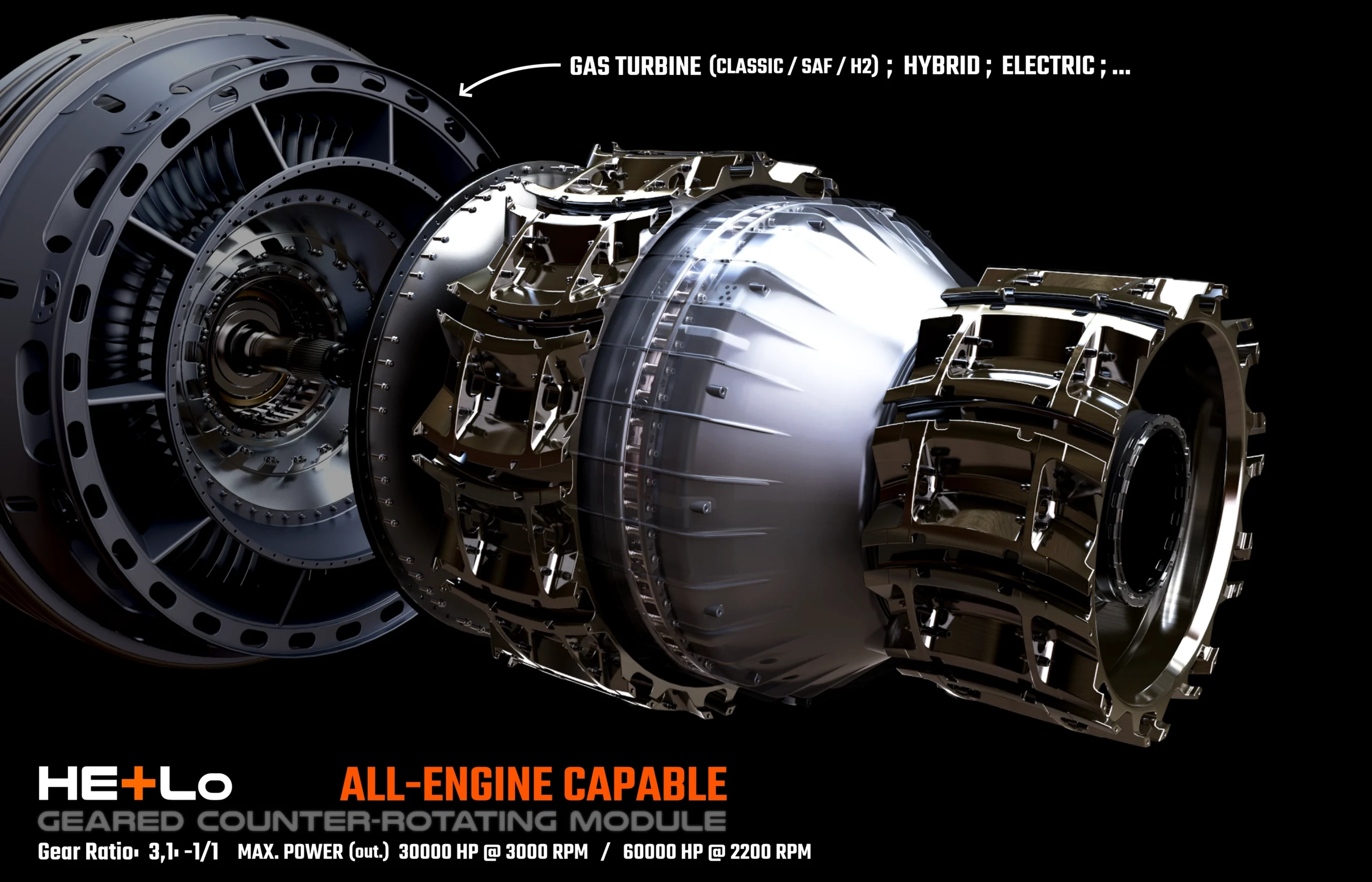

MORE THAN A SPEED REDUCER,

RADIAL GEARBOX

IS A FAN REDUCER

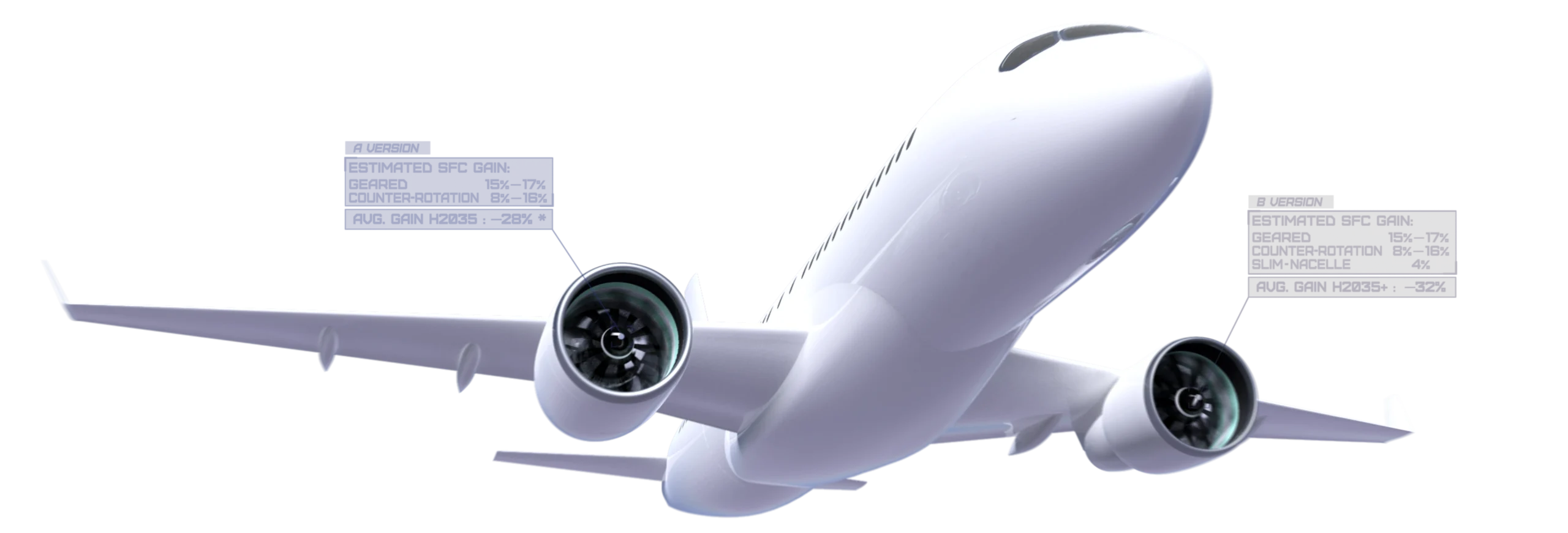

>> TARGET H2035

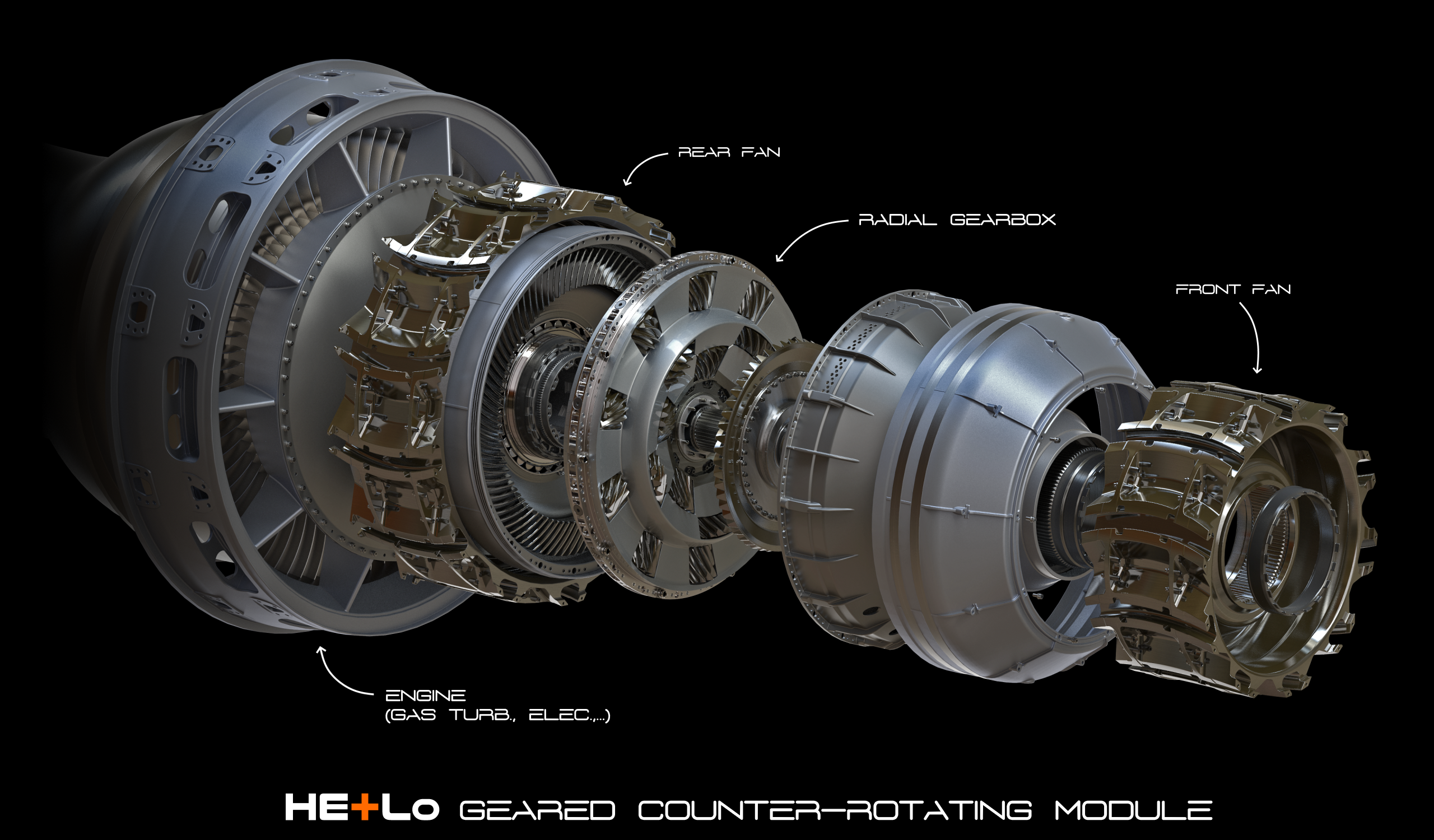

‘H2035’ AIRCRAFT POWERED BY

HE+Lo

PROPULSORS

-28% or -32% SFC GAIN

/ * by propulsor alone, with conventional nacelle (#A) or short-nacelle (#B) – vs. ref. 2000

Conventional engine integration =

LOW RISK + H2035 READY + ENABLE RE-MOTORIZING

SFC gain improvement possibility =

INVERTIBLE FAN + SLIM-NACELLE (#B), BLI or OPEN-FAN

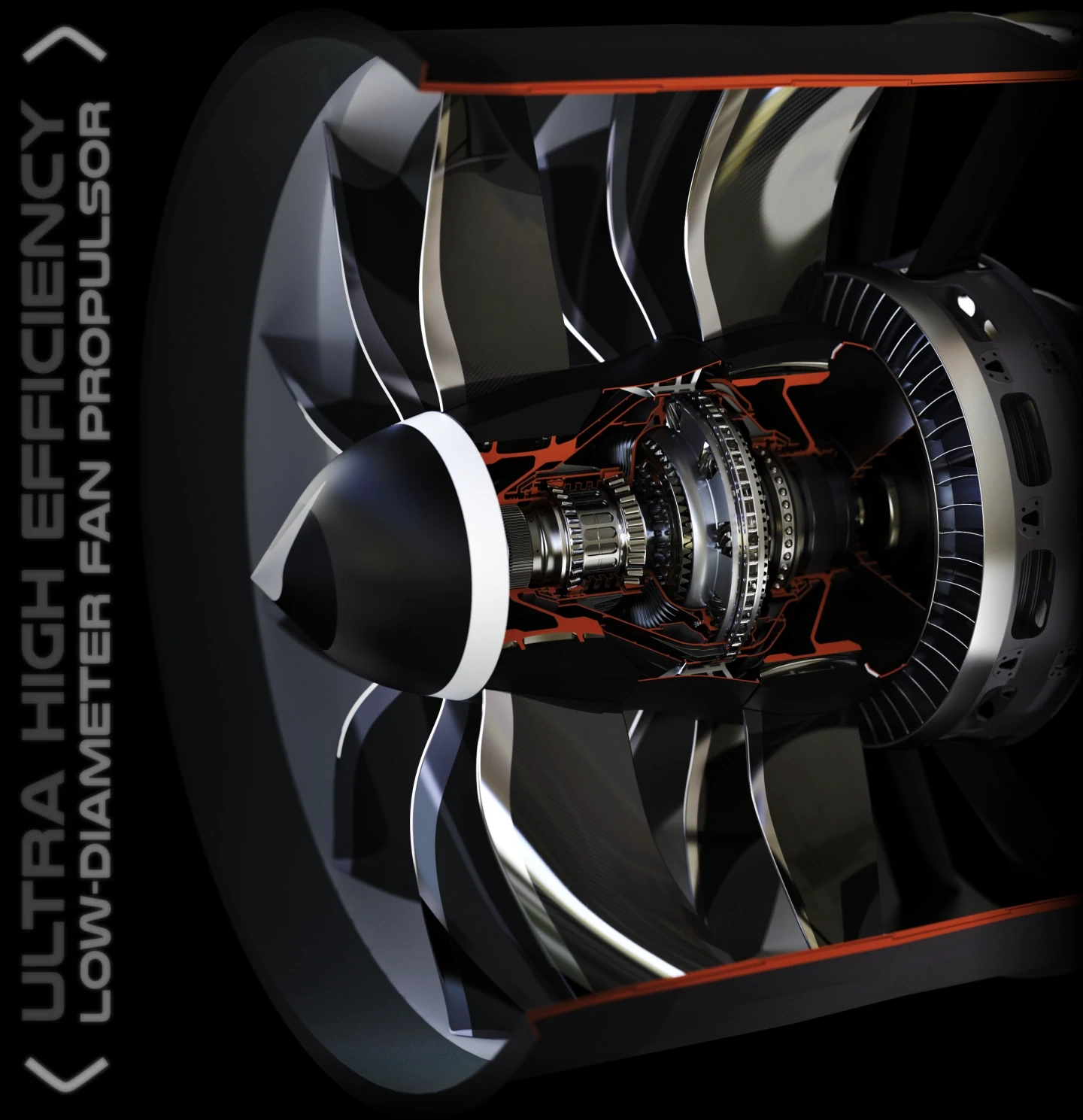

HE+Lo

HIGH EFFICIENCY LOW-DIAMETER FAN AIRCRAFT PROPULSOR

Born from the sole requirements of commercial aircraft engines,

The RADIAL GEARBOX speed reducer concept has been specifically designed to durably reduce the speed of an aircraft fan.

The RADIAL GEARBOX speed reducer concept has been specifically designed to durably reduce the speed of an aircraft fan.

Advantageously, it can also be used to drive a Contra-rotating Doublet,

offering both maximum propulsive efficiency,

and an « Ultra-High Bypass Ratio » with a minimized fan diameter.

offering both maximum propulsive efficiency,

and an « Ultra-High Bypass Ratio » with a minimized fan diameter.

Disruptive thrust reverser

To maximize propulsive efficiency through

a Slim-Nacelle, BLI, or Open-Fan configuration,

A Bypass REVERSER can achieve thrust reversal

by changing the direction of fan rotation.

a Slim-Nacelle, BLI, or Open-Fan configuration,

A Bypass REVERSER can achieve thrust reversal

by changing the direction of fan rotation.

Enabled by the ‘Geared Fan’ technology which reduces fan inertia,

the Bypass REVERSER ensures secure power transmission

between the engine and the fan when not in use.

the Bypass REVERSER ensures secure power transmission

between the engine and the fan when not in use.

In a Slim-Nacelle underwing configuration, the HE+Lo Propulsor

enables a 16% reduction in SFC compared to current engines

enables a 16% reduction in SFC compared to current engines

CORE-INTEGRATED VAFN

Geared counter-rotation being ideally suited

for high-efficiency low-FPR fans,

an integrated Variable Area Fan Nozzle has been designed

to maintain an acceptable operational margin

without affecting the aerodynamic efficiency of the nacelle.

Since counter-rotation allows for a smaller variation range,

an FPR < 1.3 can be achieved with only a 10% variation in geometry.

for high-efficiency low-FPR fans,

an integrated Variable Area Fan Nozzle has been designed

to maintain an acceptable operational margin

without affecting the aerodynamic efficiency of the nacelle.

Since counter-rotation allows for a smaller variation range,

an FPR < 1.3 can be achieved with only a 10% variation in geometry.

>> WHY THIS PROJECT ?

A RE-IMAGINED « POWER GEARBOX »...

Because «geared» a modern fan represents the most severe specifications ever encountered for gears,

and because the very universal ‘Planetary’ gearbox has never been used at this power level in an aircraft.

The geared fan being essential to the future ultra-frugal commercial aircrafts,

it was essential to know if a reduction system, specifically dedicated to this extreme application, was conceivable.

We have dared this audacious and uncertain adventure, with today’s conditions.

and because the very universal ‘Planetary’ gearbox has never been used at this power level in an aircraft.

The geared fan being essential to the future ultra-frugal commercial aircrafts,

it was essential to know if a reduction system, specifically dedicated to this extreme application, was conceivable.

We have dared this audacious and uncertain adventure, with today’s conditions.

...advantageously benefiting from counter-rotation

« As soon as energy costs and/or environmental requirements compensate over-complexity of this technology,

this propulsion will become inevitable ».

These are the conclusions of all the studies carried out on the counter-rotating fans over the past 30 years.

In addition to its uncontested propulsive efficiency and its predisposition for the low-FPR fan,

The main advantage of an active doublet is its compact fan diameter,

guaranteeing engine integration (ducted or not) and hyperveloce LP shaft with limited PGB gear ratio.

Merging the « Geared fan » becoming essential with this propulsion, was therefore ideal.

this propulsion will become inevitable ».

These are the conclusions of all the studies carried out on the counter-rotating fans over the past 30 years.

In addition to its uncontested propulsive efficiency and its predisposition for the low-FPR fan,

The main advantage of an active doublet is its compact fan diameter,

guaranteeing engine integration (ducted or not) and hyperveloce LP shaft with limited PGB gear ratio.

Merging the « Geared fan » becoming essential with this propulsion, was therefore ideal.

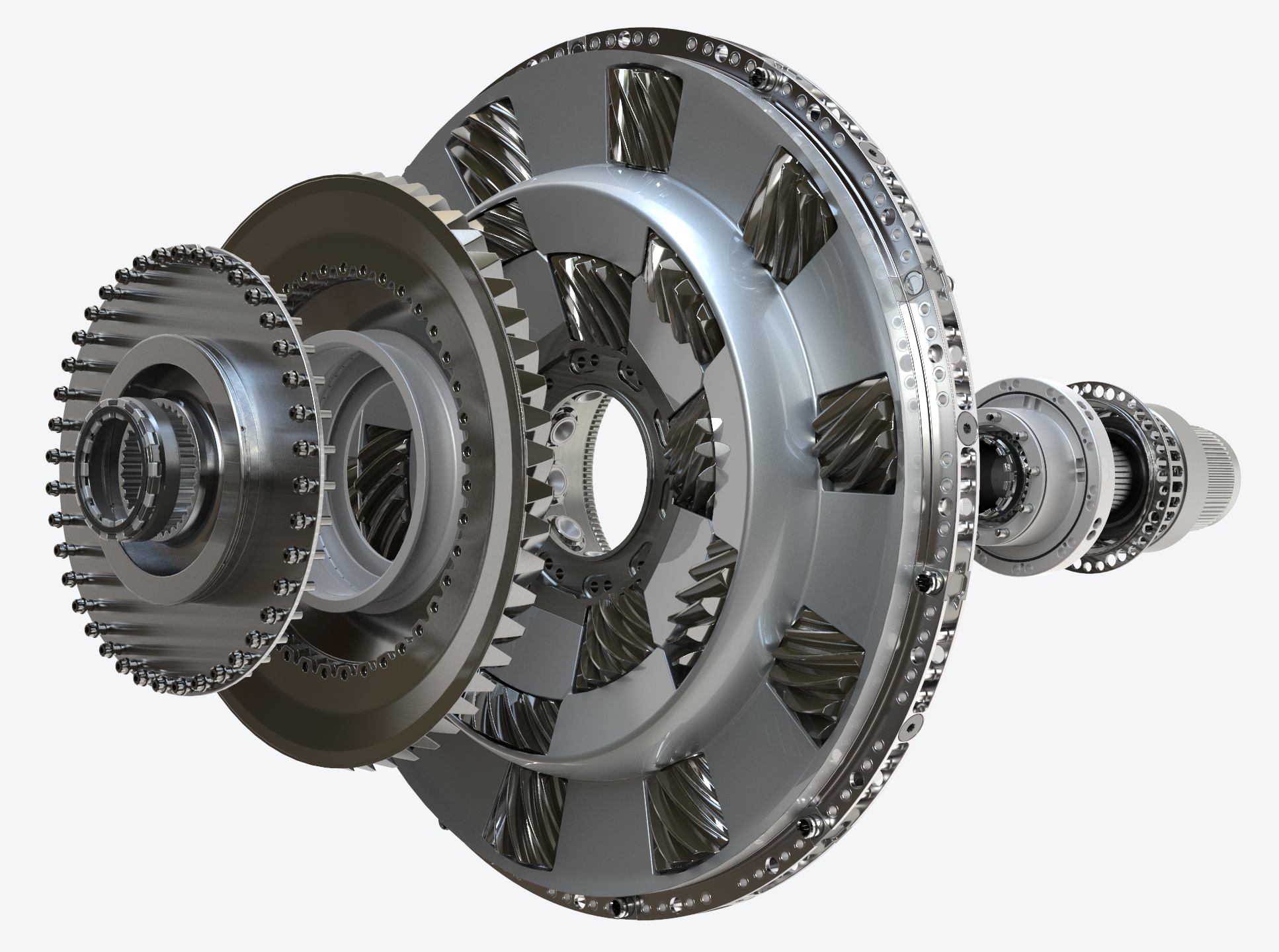

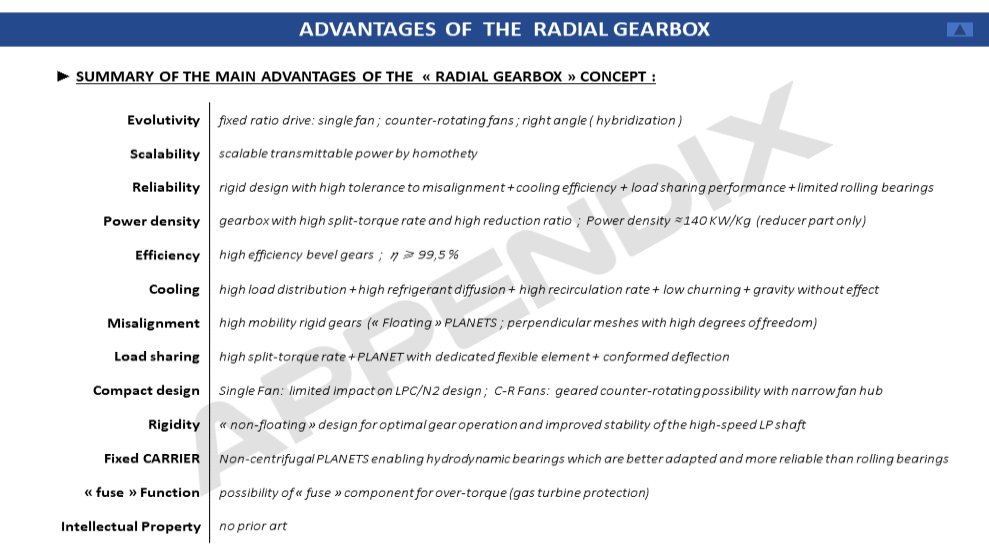

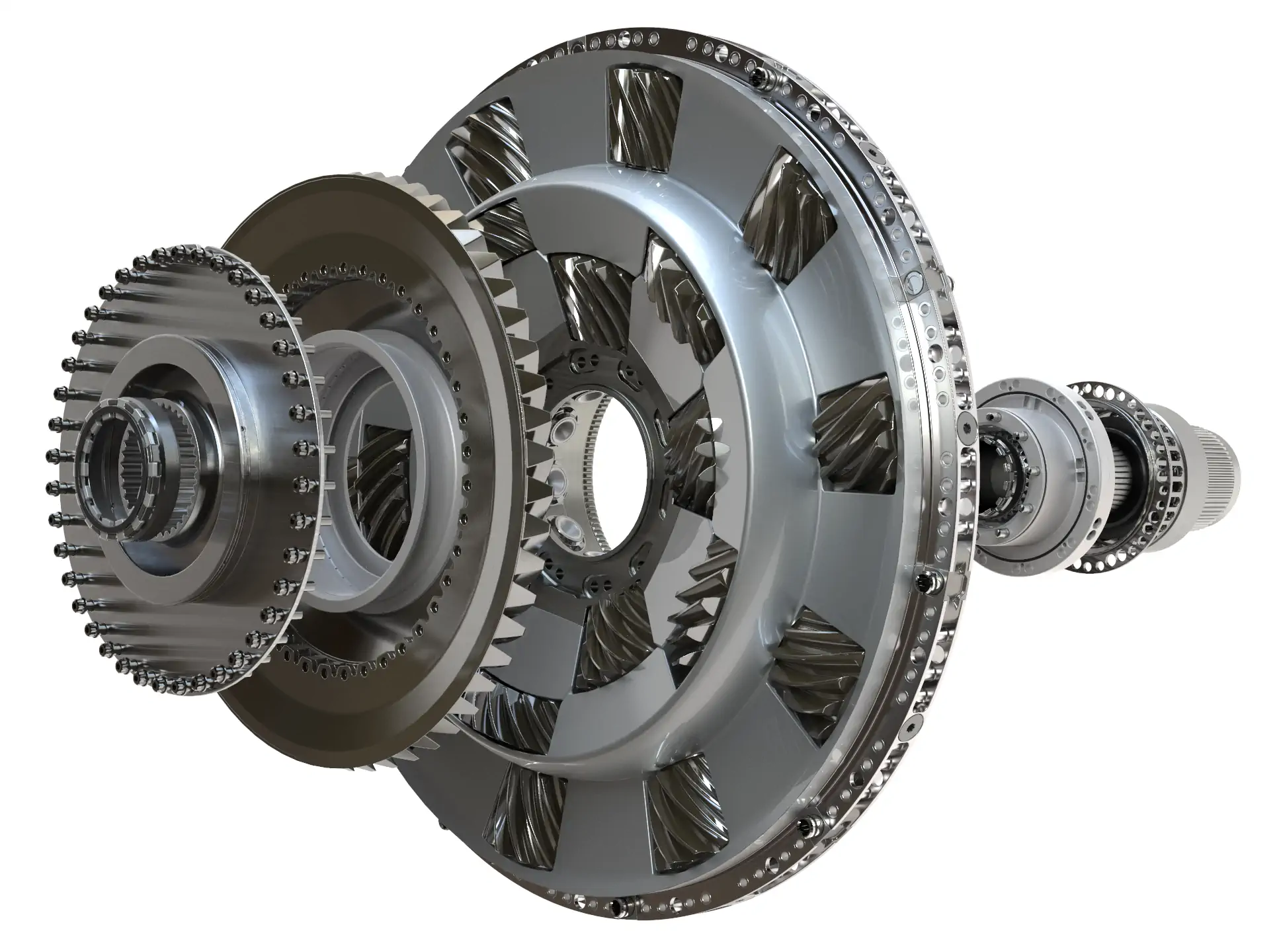

>> HEART OF THE CONCEPT: THE RADIAL GEARBOX

an elegant counter-intuitive gearbox

A Fixed reduction ratio of 3:1, and a very high power density enabled by a highly divided and uniformly distributed engine torque (lightly affected risk) are essential for the targeted application.

The counter-rotating RADIAL GEARBOX definitely represents a serious alternative for very high efficiency, robust and compact propulsion of H2035+ commercial aircraft engines.

>> focus on…

H2035 READY

The goal of this project was to propose a propulsor

disruptive enough to be effective,

evolutive enough to be durable,

and pragmatic enough to guarantee H2035.

Made possible by the Radial Gearbox innovation,

and by allowing a gain of 16% SFC vs current,

HE+Lo offers a compromise that is all the more relevant in that it would allow retrofitting of the LEAP and GTF, should this option become advantageous.

disruptive enough to be effective,

evolutive enough to be durable,

and pragmatic enough to guarantee H2035.

Made possible by the Radial Gearbox innovation,

and by allowing a gain of 16% SFC vs current,

HE+Lo offers a compromise that is all the more relevant in that it would allow retrofitting of the LEAP and GTF, should this option become advantageous.

DISRUPTIVE THRUST REVERSER

By directly reversing thrust by inverting the direction of rotation of the fans, the REVERSER module enables Slim-Nacelle, Open-Fan or BLI configuration.

The REVERSER Bypass is a classic mechanical coupling, as long as it is not activated, to secure the transmission for other flight phases.

Spec’s (30K ver.) : Weight 85Kg – Tmax. Rev. mode 35%Tnom. – Max. Speed 9000 RPM

The REVERSER Bypass is a classic mechanical coupling, as long as it is not activated, to secure the transmission for other flight phases.

Spec’s (30K ver.) : Weight 85Kg – Tmax. Rev. mode 35%Tnom. – Max. Speed 9000 RPM

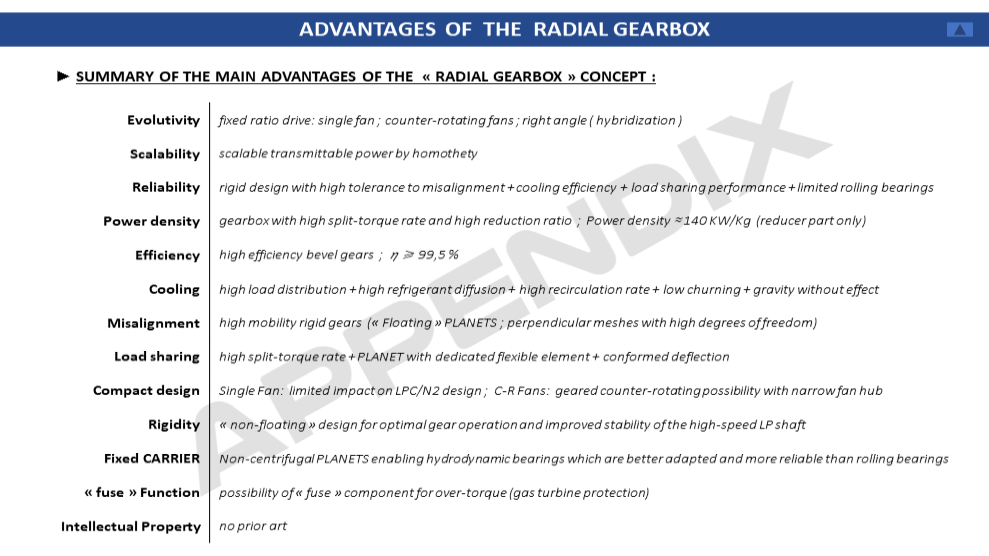

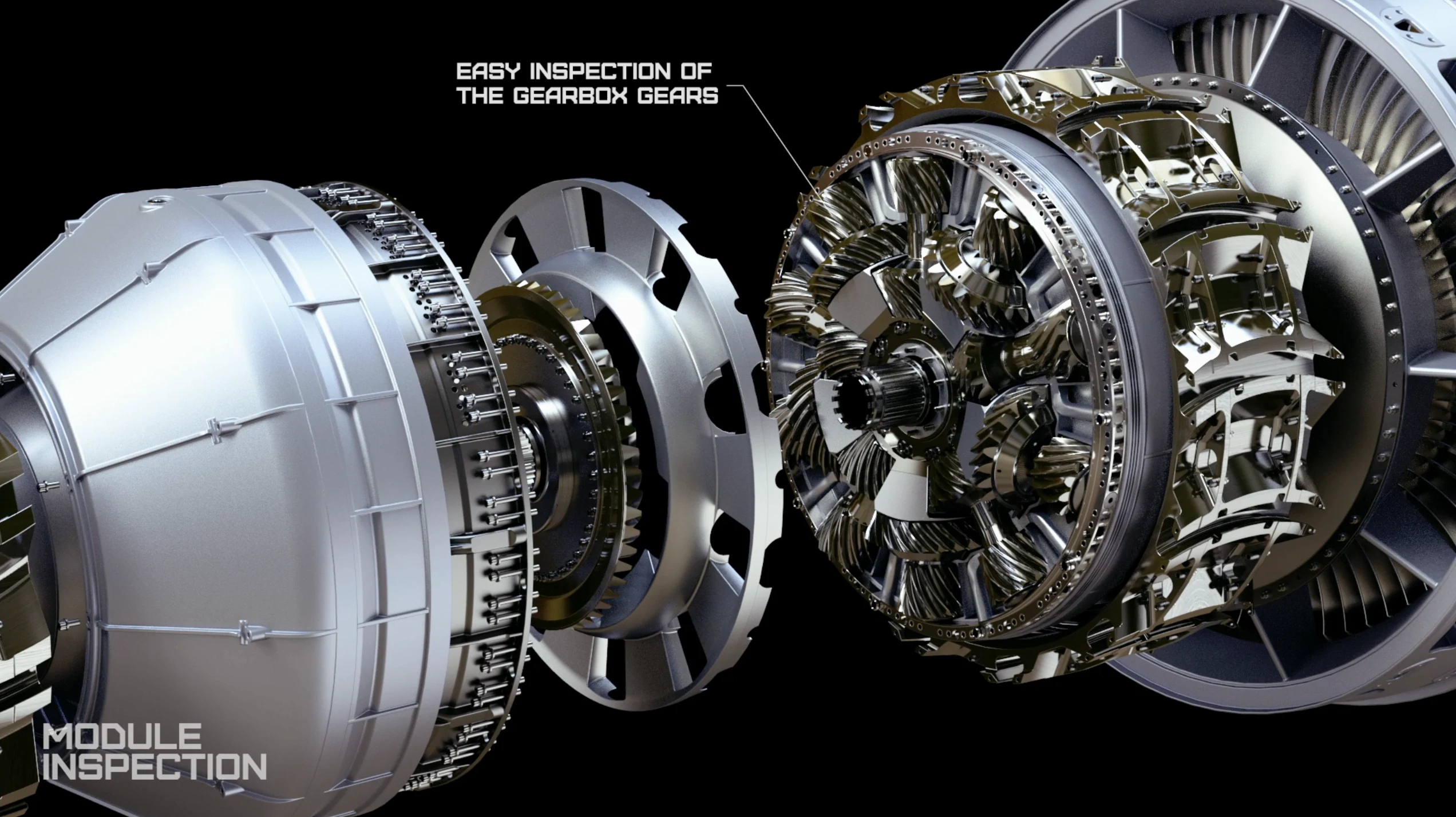

MODULAR CONCEPT

Focus on Compatibility!

The innovative architecture of the RADIAL GEARBOX speed reducer has been specifically created to satisfy the power density, cooling and highly disturbed environment requirements of a Turbofan. Compatible with all types of engines,

it represents a serious alternative for tomorrow’s ultra-frugal aircrafts.

The innovative architecture of the RADIAL GEARBOX speed reducer has been specifically created to satisfy the power density, cooling and highly disturbed environment requirements of a Turbofan. Compatible with all types of engines,

it represents a serious alternative for tomorrow’s ultra-frugal aircrafts.

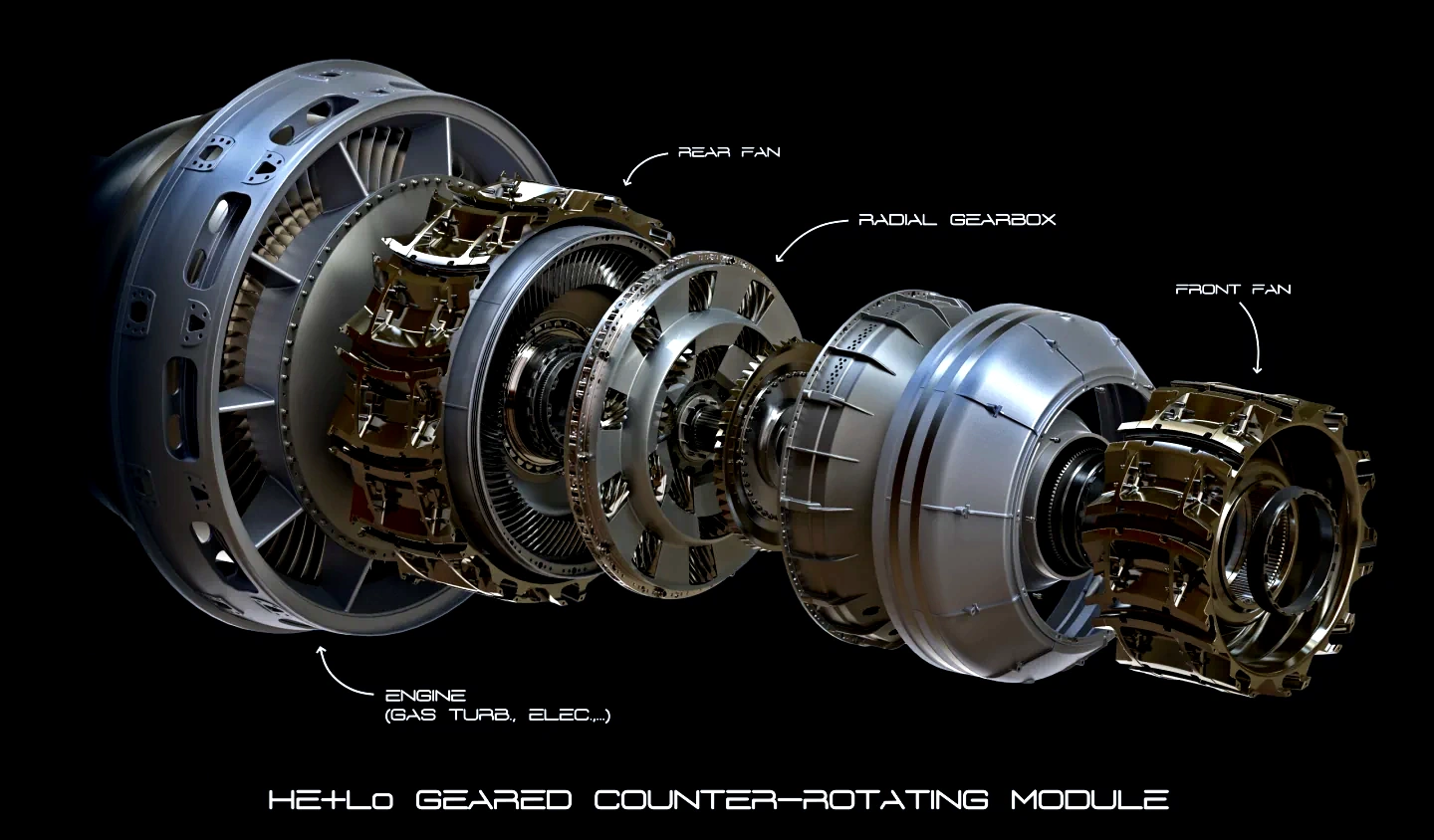

HE+Lo ─ CLOSER LOOK

A closer look on the assembly and fluids circulation of the HE+Lo Propulsor module…

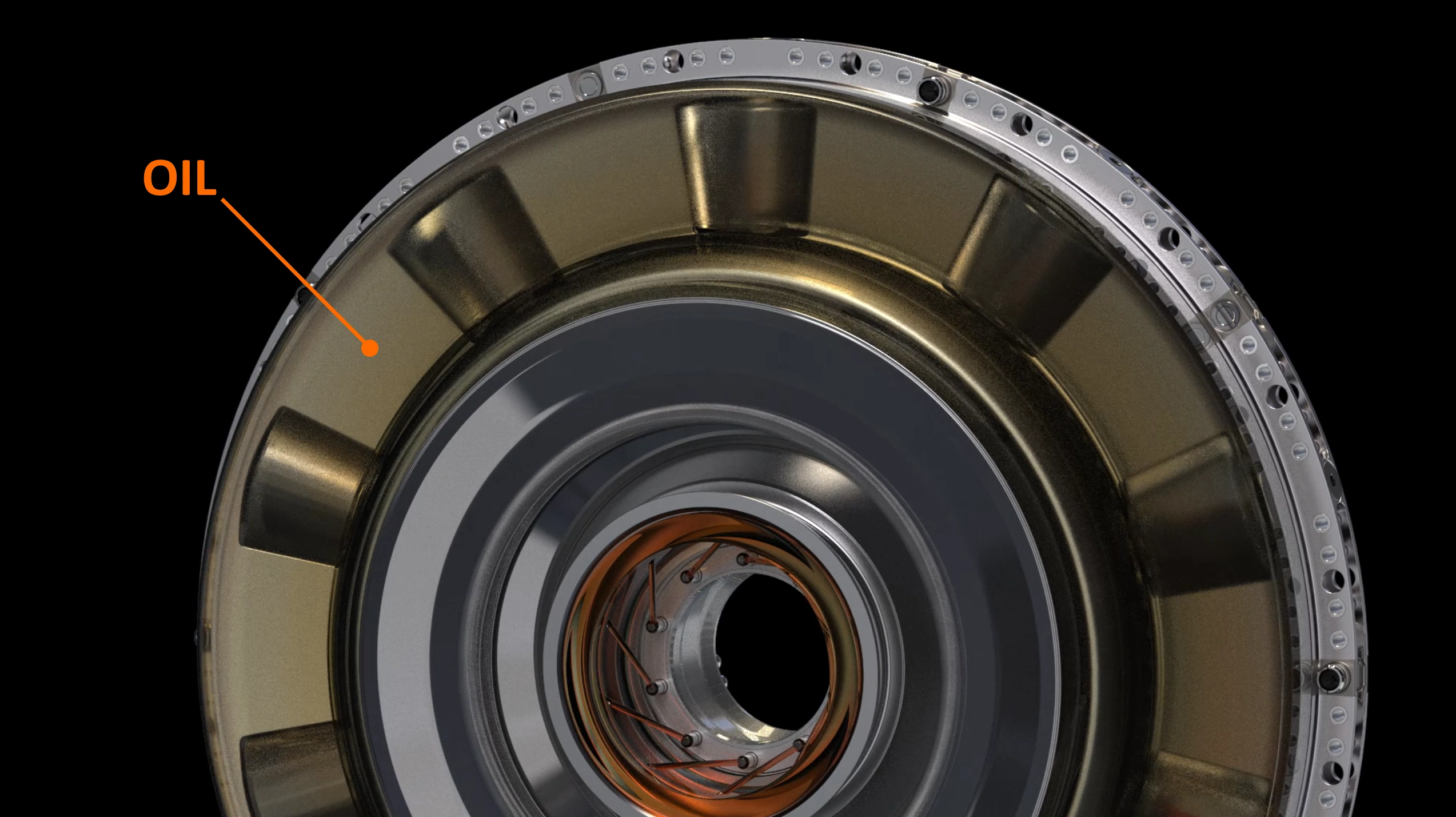

RADIAL COOLING

Focus on the cooling efficiency !

Oil is centrifuged directly between the teeth of the SUN and spreads uniformly in the gearbox. Centrifugal effect, helical gears and casings lead the oil through the input stage and then through the output stage.

Result: optimal cooling and recirculation, no churning, no gravity effect.

Oil is centrifuged directly between the teeth of the SUN and spreads uniformly in the gearbox. Centrifugal effect, helical gears and casings lead the oil through the input stage and then through the output stage.

Result: optimal cooling and recirculation, no churning, no gravity effect.

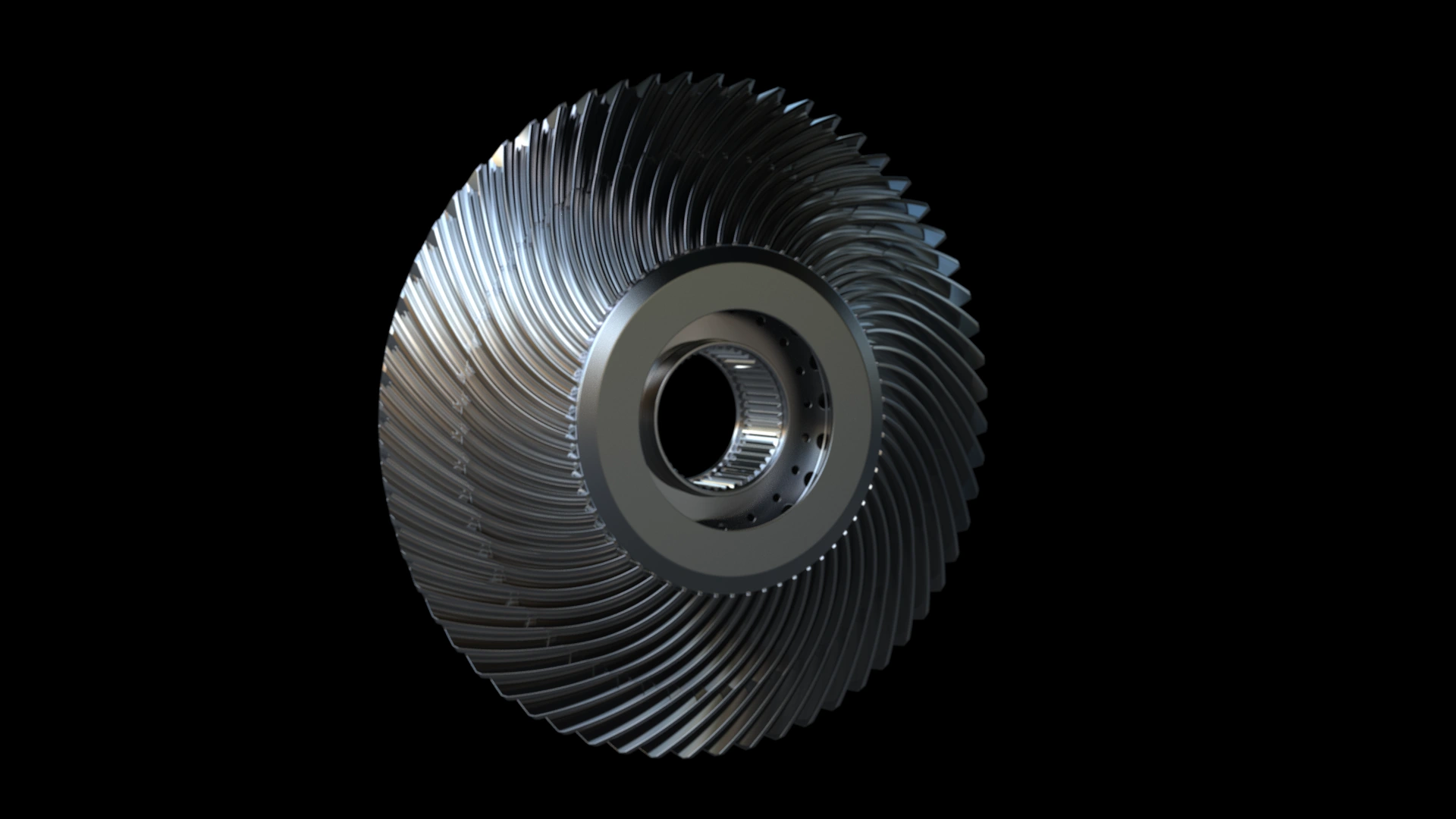

SUN 30KHP@10KRPM

Focus on the input gear of the RADIAL GEARBOX !

The injection of centrifuged oil directly between the gear meshes cools the 110KW of heat loss of the first stage very efficiently…

The injection of centrifuged oil directly between the gear meshes cools the 110KW of heat loss of the first stage very efficiently…

Our objectives have now been achieved, and we are looking to transfer this intellectual property to any interested investor *

We thank you for your interest in this technology and remain at your disposal to provide any further information you may require.

Deadline PCT National Phase :

LOCATION :

- 5D, AV. de la RESISTANCE 91700 STE-GENEV-DES-BOIS FRANCE

CONTACT :

- radialgearbox@gmail.com

* Note: The company needs to be sufficiently protected against NIH syndrome

© 2025 RADIAL GEARBOX ALL RIGHT RESERVED — Site powered by LucasWeb

RADIAL GEARBOX

INNOVATIVE POWER GEARBOX FOR NEXT-GEN ENGINES

PRESENTS THE INNOVATION FOR SALE

HE+Lo

HIGH EFFICIENCY LOW-DIAMETER FAN AIRCRAFT PROPULSOR

not the most efficient, but the best compromise.

MORE THAN A SPEED REDUCER,

RADIAL GEARBOX

IS A FAN REDUCER

TARGET H2035

H2035 AIRCRAFT POWERED BY

HE+Lo

PROPULSORS

-28% or -32% SFC GAIN

LOW RISK + H2035 READY

+ ENABLE RE-MOTORIZING

+ POSSIBILITY of INVERTIBLE FAN with SLIM-NACELLE, BLI or OPEN-FAN

* propulsor alone /vs year 2000 ref. engine

HE+Lo

HIGH EFFICIENCY LOW-DIAMETER FAN AIRCRAFT PROPULSOR

Born from the sole requirements of the commercial aircraft engines,

the ‘RADIAL GEARBOX’ speed reducer concept has been imagined to durably reduce an aircraft fan.

Advantageously, it can be used to drive a Countrarotating Doublet offering both,

the ‘RADIAL GEARBOX’ speed reducer concept has been imagined to durably reduce an aircraft fan.

Advantageously, it can be used to drive a Countrarotating Doublet offering both,

propulsion with maximum efficiency,

and an « Ultra-High Bypass Ratio » with a minimized fan diameter.

and an « Ultra-High Bypass Ratio » with a minimized fan diameter.

Disruptive thrust reverser

With the aim of completing the concept and maximizing propulsive efficiency with a Slim-Nacelle, Open-Fan or BLI configuration,

A Bypass REVERSER can be used to reverse the thrust of the aircraft, by changing the direction of rotation of the fan.

A Bypass REVERSER can be used to reverse the thrust of the aircraft, by changing the direction of rotation of the fan.

In under-wing Slim-Nacelle configuration, the HE+Lo propulsor achieves a 16% reduction in SFC compared to current engines.

CORE-INTEGRATED VAFN

Geared counter-rotation being perfectly suited to highly efficient low-FPR fans,

We have finalized the technological offer by taking advantage of the HE+Lo propulsor and its slim-nacelle, to design the simplest possible variable geometry, without affecting the aerodynamic efficiency of the nacelle.

Thanks to the counter-rotating doublet, only 10% variation of ‘fan nozzle area’ is needed to achieve an FPR <1.3 with an acceptable operational margin.

We have finalized the technological offer by taking advantage of the HE+Lo propulsor and its slim-nacelle, to design the simplest possible variable geometry, without affecting the aerodynamic efficiency of the nacelle.

Thanks to the counter-rotating doublet, only 10% variation of ‘fan nozzle area’ is needed to achieve an FPR <1.3 with an acceptable operational margin.

WHY THIS PROJECT?

A RE-IMAGINED « POWER GEARBOX »...

Because «geared» a modern fan represents the most severe specifications ever encountered for gears,

and because the very universal ‘Planetary’ gearbox has never been used at this power level in an aircraft.

The geared fan being essential to the future ultra-frugal commercial aircrafts,

it was essential to know if a reduction system, specifically dedicated to this extreme application, was conceivable.

We have dared this audacious and uncertain adventure, with today’s conditions.

and because the very universal ‘Planetary’ gearbox has never been used at this power level in an aircraft.

The geared fan being essential to the future ultra-frugal commercial aircrafts,

it was essential to know if a reduction system, specifically dedicated to this extreme application, was conceivable.

We have dared this audacious and uncertain adventure, with today’s conditions.

...advantageously benefiting from counter-rotation

« As soon as energy costs and/or environmental requirements compensate over-complexity of this technology, this propulsion will become inevitable ».

These are the conclusions of all the studies carried out on the counter-rotating fans over the past 30 years.

In addition to its uncontested propulsive efficiency and its predisposition for the low-FPR fan,

The main advantage of an active doublet is its compact fan diameter, guaranteeing engine integration (ducted or not) and hyperveloce LP shaft with limited PGB gear ratio.

Merging the « Geared fan » becoming essential with this propulsion, was therefore ideal.

These are the conclusions of all the studies carried out on the counter-rotating fans over the past 30 years.

In addition to its uncontested propulsive efficiency and its predisposition for the low-FPR fan,

The main advantage of an active doublet is its compact fan diameter, guaranteeing engine integration (ducted or not) and hyperveloce LP shaft with limited PGB gear ratio.

Merging the « Geared fan » becoming essential with this propulsion, was therefore ideal.

RADIAL GEARBOX

CONCEPT

CONCEPT

a counter-intuitive gearbox

A Fixed reduction ratio of 3:1, and a very high power density enabled by a highly divided and uniformly distributed engine torque (lightly affected risk) , are essential for the targeted application.

However,

The ‘RADIAL’ Planets offering fundamental advantages such as a high misalignment tolerance of the gear meshes,

an optimal geared counter-rotation,

and a maximized cooling efficiency,

The ‘RADIAL’ Planets offering fundamental advantages such as a high misalignment tolerance of the gear meshes,

an optimal geared counter-rotation,

and a maximized cooling efficiency,

The counter-rotating RADIAL GEARBOX definitely represents a serious alternative for very high efficiency, robust and compact propulsion of H2035+ commercial aircraft engines.

FOCUS ON…

H2035 READY

The goal of this project was to propose a propulsor

disruptive enough to be effective,

evolutive enough to be durable,

and pragmatic enough to guarantee H2035.

Made possible by the Radial Gearbox innovation,

and by allowing a gain of 16% SFC vs current,

HE+Lo offers a compromise that is all the more relevant in that it would allow retrofitting of the LEAP and GTF, should this option become advantageous.

disruptive enough to be effective,

evolutive enough to be durable,

and pragmatic enough to guarantee H2035.

Made possible by the Radial Gearbox innovation,

and by allowing a gain of 16% SFC vs current,

HE+Lo offers a compromise that is all the more relevant in that it would allow retrofitting of the LEAP and GTF, should this option become advantageous.

ROBUST CONCEPT

- Non-differential and synchronous gear ratio, preferable for counter-rotation

- High power density and high efficiency

- Ultra compact design, compatible with ‘small core’ engine

- Only 6 rolling bearings (limited DN) in the entire module

- High tolerance to gear mesh misalignment

- Optimized cooling

DISRUPTIVE THRUST REVERSER

By directly reversing thrust by inverting the direction of rotation of the fans, the REVERSER module enables Slim-Nacelle, Open-Fan or BLI configuration.

The REVERSER Bypass is a classic mechanical coupling, as long as it is not activated, to secure the transmission for other flight phases.

Spec’s (30K ver.) : Weight 85Kg – Tmax. Rev. mode 35%Tnom. – Max. Speed 9000 RPM

The REVERSER Bypass is a classic mechanical coupling, as long as it is not activated, to secure the transmission for other flight phases.

Spec’s (30K ver.) : Weight 85Kg – Tmax. Rev. mode 35%Tnom. – Max. Speed 9000 RPM

MODULAR CONCEPT

Focus on Compatibility!

The innovative architecture of the RADIAL GEARBOX speed reducer has been specifically created to satisfy the power density, cooling and highly disturbed environment requirements of a Turbofan. Compatible with all types of engines, it represents a serious alternative for tomorrow’s ultra-frugal aircrafts.

The innovative architecture of the RADIAL GEARBOX speed reducer has been specifically created to satisfy the power density, cooling and highly disturbed environment requirements of a Turbofan. Compatible with all types of engines, it represents a serious alternative for tomorrow’s ultra-frugal aircrafts.

RADIAL COOLING

Focus on the cooling efficiency !

Oil is centrifuged directly between the teeth of the SUN and spreads uniformly in the gearbox. Centrifugal effect, helical gears and casings lead the oil through the input stage and then through the output stage.

Result: optimal cooling and recirculation, no churning, no gravity effect.

Oil is centrifuged directly between the teeth of the SUN and spreads uniformly in the gearbox. Centrifugal effect, helical gears and casings lead the oil through the input stage and then through the output stage.

Result: optimal cooling and recirculation, no churning, no gravity effect.

SUN 30KHP@10KRPM

Focus on the input gear of the RADIAL GEARBOX !

The injection of centrifuged oil directly between the gear meshes cools the 110KW of heat loss of the first stage very efficiently…

The injection of centrifuged oil directly between the gear meshes cools the 110KW of heat loss of the first stage very efficiently…

HE+Lo ─ CLOSER LOOK

A closer look on the assembly and fluids circulation of the HE+Lo Propulsor module…

Our objectives have now been achieved, and we are looking to transfer this intellectual property to any interested investor *

We thank you for your interest in this technology and remain at your disposal to provide any further information you may require.

Deadline PCT National Phase :

LOCATION

5D, AV. de la RESISTANCE

91700 STE-GENEV-DES-BOIS FRANCE

91700 STE-GENEV-DES-BOIS FRANCE

CONTACT

radialgearbox@gmail.com

* Note: The company needs to be sufficiently protected against NIH syndrome

© 2025 RADIAL GEARBOX ALL RIGHT RESERVED

Site powered by LucasWeb